Disposable coveralls have become an essential part of the personal protective equipment (PPE) used across different industries. They are designed to provide a barrier against hazardous materials and infectious agents, making them an important aspect of workplace safety. Coveralls are used across diverse sectors, from healthcare to chemical manufacturing. They offer an effective way to prevent contamination and minimize the potential for accidents. Selecting the right coverall material is critical in ensuring maximum protection for professionals in every field. Here, we take a look at the different types of materials that are used for disposable coveralls.

- Polypropylene

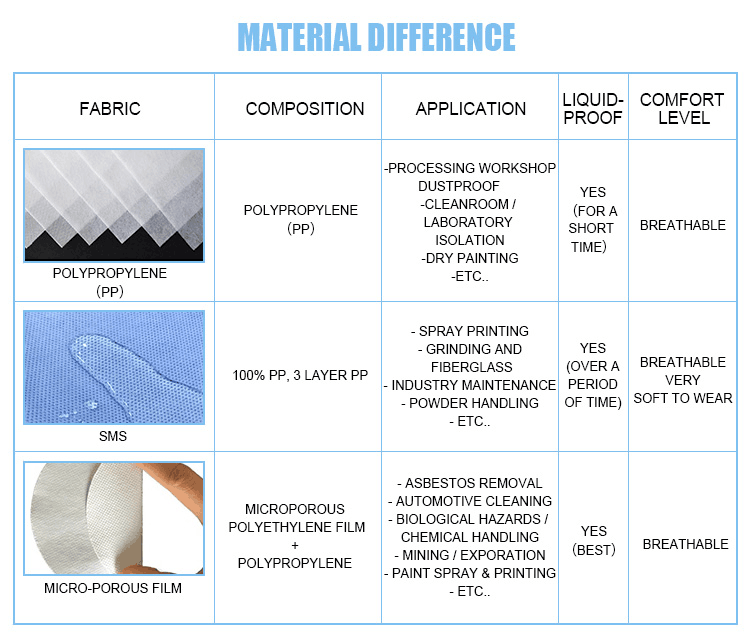

Polypropylene is the most commonly used material for disposable coveralls. It is a lightweight, breathable, and cost-effective synthetic fabric that offers excellent penetration resistance against both water and chemicals. Polypropylene coveralls are ideal for applications that require minimal protection against hazardous materials. They are mostly used in hospitals, labs, and food processing facilities.

- Polyethylene

Polyethylene is a plastic material that is known for its low cost, durability, and moisture resistance properties. It is a popular material for disposable garments as it provides an impermeable barrier against water and hazardous chemicals. Polyethylene coveralls are ideal for use in wet environments, such as cleaning up spills or handling chemicals.

- Microporous film

Microporous film is a breathable and lightweight material that offers superior protection against hazardous materials, including liquids, chemicals, and particulates. It is designed to allow the passage of air and water vapor while preventing the penetration of liquids and solids. Microporous film coveralls are used in industries such as pharmaceutical manufacturing, nuclear facilities, and cleanrooms.

- Tyvek

Tyvek is a unique material that is created by combining polyethylene fibers. It is a lightweight, tear-resistant, and breathable material that provides an excellent barrier against water, chemicals, and particulates. Tyvek coveralls are used across a range of industries, including construction, asbestos removal, and hazardous waste cleanup.

- SMS

SMS stands for “spunbound-meltblown-spunbound,” which is a type of non-woven fabric that consists of three layers. The spunbound layer provides strength and durability, the meltblown layer offers exceptional filtration properties, and the outer spunbound layer offers protection against fluids and particulates. SMS coveralls are an excellent choice for the medical, pharmaceutical, and electronics industries.

- Polyvinyl chloride (PVC)

Polyvinyl chloride, commonly referred to as PVC, is a plastic material that is often used in disposable coveralls due to its resistance to chemicals and oils. It offers an excellent barrier against liquids and particulates and is ideal for use in industries such as chemical manufacturing, petrochemicals, and oil refining.

Selecting the right material for disposable coveralls is essential to ensure maximum protection against hazardous materials and prevent the spread of infectious diseases. The choice of material will depend on several factors, including the level of protection required, the environment, and the application. When choosing a disposable coverall, it’s essential to consider the material’s breathability, durability, and resistance to chemicals and particulates. To ensure the best protection, always choose a coverall that is certified by relevant regulatory bodies and meets industry standards.