When it comes to protective clothing, the importance of proper seams cannot be overstated. Seams that are poorly constructed or not up to the required standard can compromise the overall effectiveness of the garment and leave workers susceptible to injury. Choosing the right type of seam is critical, and it can play a significant role in ensuring the highest level of protection.

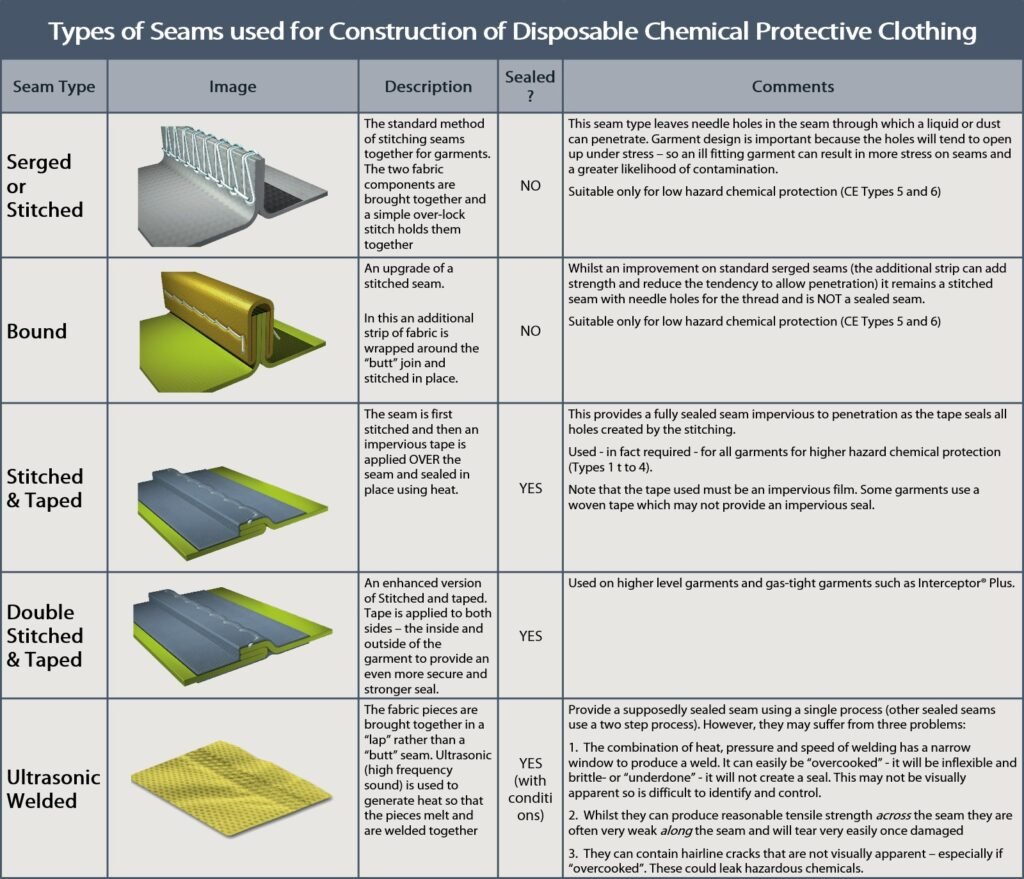

There are several types of seams used in protective clothing, including flat, abutted, overlapped, and taped. Each of these seams has its advantages and disadvantages; however, some provide a higher level of protection than others.

The flat seam is a simple and the most common type of seam used in protective clothing. In this seam, the fabric pieces are laid flat on top of one another and sewn together with a straight stitch. Flat seams are easy to construct and require minimal fabric, but they do not offer the highest level of protection. Flat seams are prone to unraveling and can increase the risk of exposure to hazardous materials.

Abutted seams are similar to flat seams but use a zigzag stitch rather than a straight stitch. Abutted seams help prevent fraying and provide better protection against hazardous materials. However, they are not as durable as other types of seams and may not be suitable for long-term use.

Overlapped seams involve overlapping two fabric pieces and sewing them together with a straight stitch. The overlapping creates an extra layer of protection against hazardous materials and helps prevent fraying. Overlapped seams are strong and durable but can be bulky and restrict movement.

Taped seams are by far the most effective type of seam when it comes to providing the highest level of protection. In this type of seam, a strip of special tape is applied over the seam to create a barrier against hazardous materials. Taped seams are strong, durable, and remain watertight even in harsh conditions. They are commonly used in chemical protective clothing for workers who are exposed to chemicals, oil, or other hazardous materials.

When choosing the right type of seam, it is essential to consider the intended use of the protective clothing. For example, if the garment is intended for short-term use, a simple flat or abutted seam may suffice. However, for long-term use in hazardous conditions, a more robust overlapped or taped seam may be more appropriate.

It is also important to consider the material of the garment when choosing the right seam. For example, different fabrics may require different types of stitches or tapes to ensure maximum protection. Nylon and other synthetic fabrics tend to have a smooth surface that makes them more difficult to bond with tapes, while natural fibers like cotton or wool may be more resistant to chemicals but less durable overall.

Finally, it is essential to ensure that the protective clothing is properly sized and fitted to the user. Poorly fitting clothing can cause discomfort, restrict movement, and compromise the effectiveness of the seams. Ensuring a proper fit will also help prevent tears or rips in the fabric, which can compromise the effectiveness of any seam.

Choosing the right type of seam is critical when it comes to providing the highest level of protection in protective clothing. While flat and abutted seams offer a basic level of protection, overlapped and taped seams provide greater durability and resistance against hazardous materials. It is important to consider the intended use of the garment, the fabric material, and the user’s fit when selecting the right seam. By selecting the right type of seam and ensuring a proper fit, workers can remain safe, comfortable, and protected while on the job.