Disposable coveralls are often used in various industries, including healthcare, food processing, and manufacturing. They provide a level of protection against hazardous substances, dirt, and other contaminants, as well as help prevent cross-contamination. These coveralls are made of different materials, each with unique features and benefits.

In this article, we will introduce the main fabrics used in protective coverall suit and the features of each.

Polypropylene

Polypropylene is a synthetic material widely used in disposable coveralls. It is a lightweight and breathable fabric that is resistant to tears and punctures, making it suitable for activities with a higher risk of skin exposure, such as spray painting, sanding, and fiberglass handling.

One of the most significant benefits of polypropylene is its liquid-resistant properties. It repels water, oils, and other liquids, protecting the wearer from spills and splashes. Additionally, polypropylene fabrics are relatively affordable, making them an excellent option for industries that require disposable protective wear.

Polyethylene

Polyethylene is a plastic-like material that is perfect for disposable coverall product. This strong and durable fabric is stain-resistant, water-resistant, and lightweight, making it a favorite in industries like food processing and healthcare.

One of the remarkable features of polyethylene fabrics is its smooth texture, which makes it comfortable to wear for extended periods. It does not absorb water or other liquids, preventing the gown or coverall from sagging or getting heavy throughout the day. Polyethylene is also resistant to acid and alkali, making it ideal for laboratories, where there is a potential for exposure to harsh chemicals.

Microporous Film

Microporous film is a laminated fabric made of polyethylene-coated polypropylene fibers. This fabric is composed of thin, flexible layers, allowing air and moisture vapor to pass through, while blocking liquids and particulates.

Microporous film is resistant to tears and punctures, making it useful in industries where sharp objects are present. It is also famous for its static-free and low-linting feature, which reduces the risk of product contamination. Additionally, microporous film is breathable and comfortable to wear, making it a favorite among people who need to wear coverall protective clothing for long hours.

Tyvek

Tyvek is a high-density polyethylene fibers spunbonded together. It is a strong, lightweight, and breathable fabric, offering excellent resistance to penetration by particles, liquids, and other harmful substances.

One of the significant advantages of Tyvek is its electrostatic dissipative properties, which reduce static build-up and prevents sparks, making it widely used in environments with static electricity risks. Additionally, Tyvek is highly resistant to water, oils, and chemicals, making it ideal for industries such as pharmaceuticals, laboratories, and agriculture.

SMS (Spunbonded-meltblown-spunbonded)

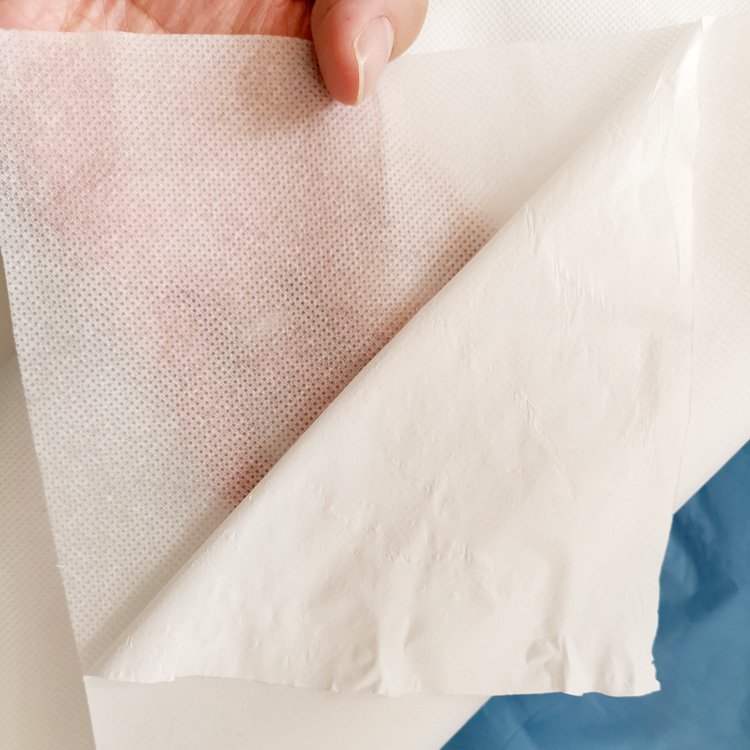

SMS is a triple-layer fabric composed of spunbonded polypropylene sandwiched between layers of meltblown polypropylene. The spunbonded layer provides strength and durability, while the meltblown layer provides a high level of filtration, blocking out microorganisms, fluids, and particulate matter.

SMS fabrics are highly breathable, water-resistant, and low-linting, making them ideal for industries that require high levels of protection, such as the medical and food processing industries. Additionally, SMS fabrics are highly cost-effective, making them a popular choice for Flame Resistant Coverall.

Disposable coveralls are essential protective gear in various industries. The material used plays a critical role in the garment’s overall effectiveness in protecting the wearer from harmful substances and contaminants. Different fabrics offer different features and benefits, such as resistance to water, oils, chemicals, static electricity, and particulate matter.

Understanding the features of each material can help industries choose the best disposable coverall for their needs, ensuring optimal protection for workers and preventing cross-contamination. Ultimately, the right disposable coverall can provide a safe and comfortable working environment while keeping hazardous substances at bay.